TOKYO, Japan – Introducing a brand-new addition to the EXBOLT string series, EXBOLT 68. The EXBOLT series is renowned for their superior repulsion and durability but with the new EXBOLT 68 we upped the power. This new addition will be available on March 8, 2024.

Similar to the EXBOLT 63 and the EXBOLT 65, the EXBOLT 68 is constructed with a proprietary material called FORGED FIBER which combines durability and quick repulsion. While thinner strings tend to have higher repulsion, there has always been the issue of low durability. FORGED FIBER was developed to solve this very issue. Ordinary nylon had a limit to the strength of its fibers, which is why Yonex reconstructed the fibers on a molecular level to build stronger bonds for lasting durability.

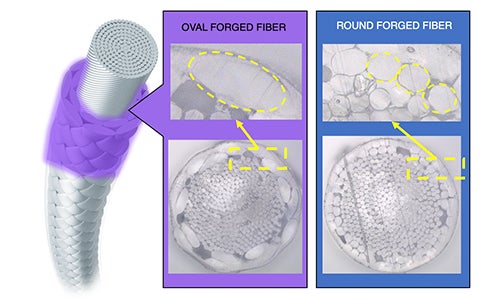

For the new EXBOLT 68, the FORGED FIBER shape has been altered from a circular pattern to an oval pattern. This new shape limits the deformation of the fiber on impact increasing overall smash power. By using an extremely durable material, the thickness of the string is reduced to improve repulsion without compromising durability. The thinner gauge compared to conventional durable strings add the repulsive feel while retaining the characteristic shuttle hold of thick gauge strings.

To increase overall control an extra coating, the Elasticity Outer, is added for increased shuttle hold. The Elasticity Outer is a coating with enhanced flexibility achieved by applying NANOALLOY technology to nylon. The result is a combination of quick repulsion, durability, and control.

With the introduction of the EXBOLT 63 we bred speed, we followed this up with a slightly more control focused string in the form of EXBOLT 65. With this new addition, we introduced a power centric string to the series. Despite its 0.68mm gauge, the EXBOLT 68 becomes the most durable string in our entire string line-up. EXBOLT now offers an option for each playstyle.

INNOVATION

FORGED FIBER

FORGED FIBER, a material developed from a fiber with high intermolecular bonding strength, durability, and heat resistance, which is also used in the forging of aircraft tires. Impurities are removed during the manufacturing process, and by stretching the material many times longer than the original material, the strength of this FORGED FIBER is greatly increased.

OVAL FORGED FIBER

The FORGED FIBER is molded in an oval shape rather than the usual circle. This oval shape limits the deformation of the fiber on impact increasing overall smash power.

Elasticity Outer

The Elasticity Outer is a coating with enhanced flexibility achieved by applying NANOALLOY technology to nylon. The result is a combination of quick repulsion, durability, and control.